How Graniterock Drives Environmental Accountability with a Digital Workflow

Customer Spotlight – Reed Carter

As an Environmental Manager for Systems and Compliance with Graniterock, Reed Carter recognizes the challenges of regulating safety and compliance across a large industrial company.

Starting in 1900 as a hard rock quarry (holding the second-oldest operating license in the state of California), Graniterock has operated consistently for over 120 years. They are recognized for providing premier building materials and construction services from Monterey, California, to the San Francisco Bay Area.

As a family-owned and operated company, respect and reliability stand at the core of Graniterock’s success in the industry over the last century. With 18 sites to manage, consistency and ease of tracking inspections and data are essential to Graniterock’s sustainability and compliance processes.

Reed oversees compliance for aggregates and construction materials division, ready-mix concrete, recycling, hot mix asphalt, and quarry operations. With nearly a decade of experience helping to mitigate risk and improve environmental compliance with Graniterock, he has seen the company grow from antiquated reporting to verifiable accountability.

Here’s how Reed experienced the transition from paper to progress at Graniterock:

Identifying performance and efficiency gaps

One of the most prominent issues with Graniterock’s inspection reporting process was the time cost. Environmental Engineers would have to visit various sites to gain insights into performance and compliance data.

Often, on-site teams wouldn’t know where to find the information engineers needed to make informed decisions and improvements across the company. Much of their time would be spent digging for vital information and updating missing inspections.

“You’d find a years’ worth of inspection forms where every box was just checked yes, yes, yes,” Reed shared.

Gaps in data, missing inspection reports and catching corrections on the fly also opened the company up to expensive corrective actions, repairs, and lawsuits.

“There is the threat of enforcement action from agencies and third parties. They come in and say, ‘you’re not doing your stormwater inspections,’ for example. And whether you are or not, they’re just going to tell you you’re not. And then you have to prove that you are doing them.”

With 20 or more different ways of tracking inspections across each site, Graniterock lacked a consistent process to verify environmental compliance and mitigate the risk of corrective actions from state and federal regulators.

Reed could see the company’s need for a reliable way to improve inspections and prove timely corrections were being made.

“You know, when you get a third party or an agency enforcement action, you’re paying based on every violation,” he said. “And if there’s 10 that are alleged and you can disprove nine of them because of good recordkeeping, then you’re only paying one.” It was time for a leap into the digital world of compliance.

Realizing the right solutions

Graniterock’s decision to move to digital inspection forms and record-keeping was just the first step in moving their operations toward the highest standard of environmental compliance.

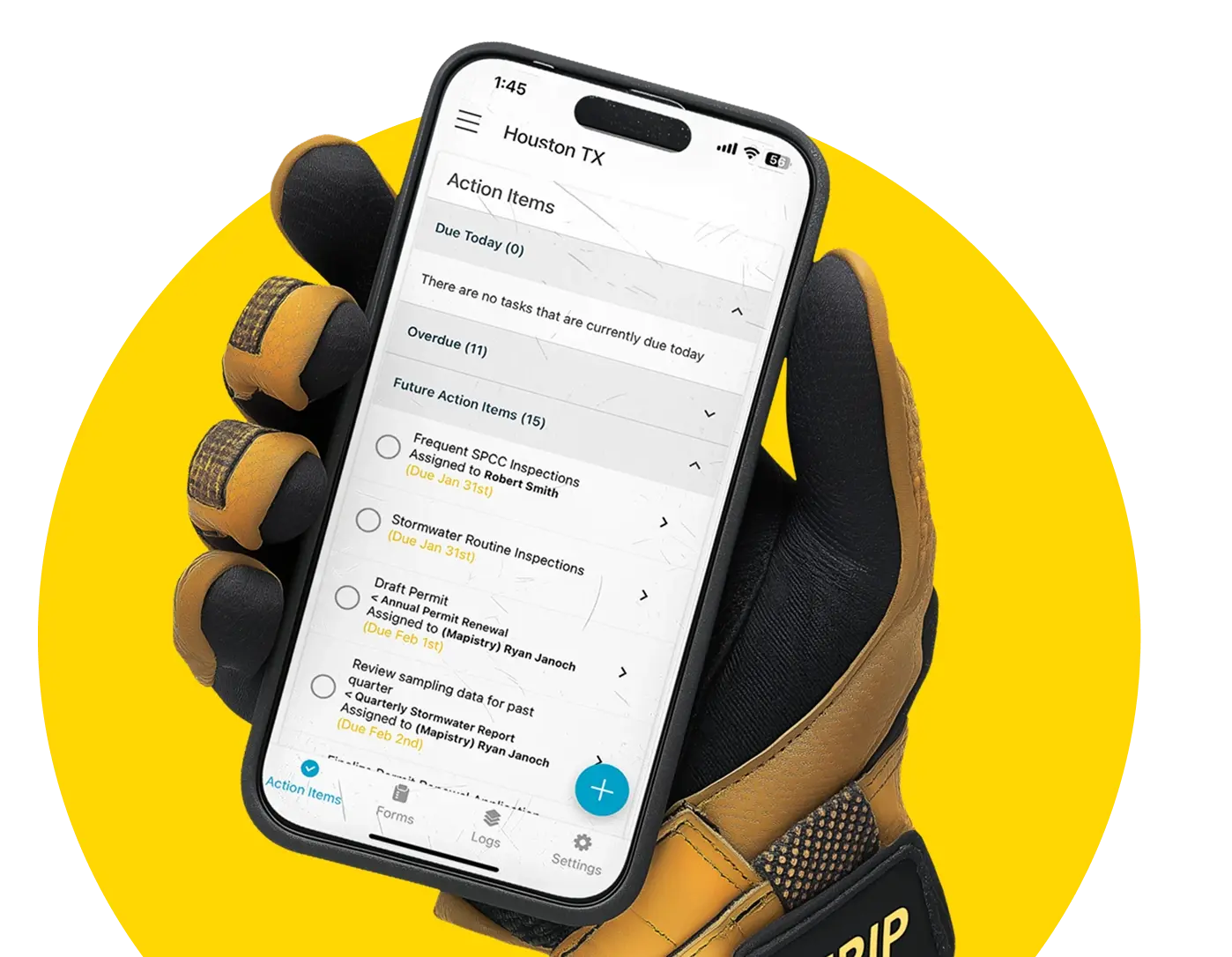

By partnering with Mapistry to create a custom dashboard to improve inspection completion rates and mitigate risks, Reed’s teams have seen increased accountability, accuracy, collaboration, and engagement in regulation maintenance and reporting across their sites.

Reed believes, since implementing Mapistry, that the overall value of time spent on inspections has improved.

He shared, “I’m a firm believer in field time. I think we’re probably spending as much time in the field as we always have. But the key is the value that you’re getting out of that field time.”

Centralized forms and data

“The really critical piece that Mapistry solves for us is having these records in the same place, where everybody can see them all at the same time,’ said Reed.

Prior to using Mapistry to upload forms, update protocols, inform site managers of changes to regulations, and to record and track data, Reed saw a gap in reliable and consistent knowledge of site staff. When making rounds to perform internal audits and gather insights into daily inspections, employees frequently couldn’t locate reports or confirm if inspections were done accurately.

Now, Mapistry provides Graniterock’s teams with a centralized dashboard to organize and quickly access important information and documents in the field. Data can even be entered offline which allows staff to hit task completion goals with ease.

Analytics are accessible to key stakeholders to assess everything from site performance metrics to individual task completion rates to inspection reports, mapping updates, emissions and stormwater test results, and more. This means environmental managers, like Reed, no longer have to scramble to fill in incomplete data when reporting to executive decision makers.

Engagement and empowerment

Leaders at Graniterock like to empower employees to be their own environmental manager and take on accountability branch-wide. If an employee sees an incomplete inspection or red X, they are more likely to check to see who’s assigned a task or go check off an inspection to ensure completion rates are 100%.

“Many operate overnight,” Reed expanded on his perspective of education-based empowerment. “We want to make sure our people know what to do at two in the morning when something fails. We want to make sure the corrective task is already in progress.”

Reed’s management style is to collaborate, not dictate. He encourages branch leaders to create their own set of expectations. The only caveat is that they set clear expectations that align with Graniterock’s high standards for environmental compliance excellence.

“We like to establish high expectations for the branches and we try to communicate those expectations for everyone on the site.” He said, “Make it easy to be accountable! I like the saying, ‘Many hands make light work.’ Involve everybody. Everybody has a stake in our environmental compliance efforts.”

- Check out Graniterock’s full case study.

- Learn how other building materials companies are streamlining compliance.

%201%20(2).png)

.png)

.svg)