Why environmental compliance is silently draining operations resources

Breaking down where manufacturers are losing six figures on compliance, and how you can cut the waste.

Rising costs are squeezing every part of your operation, and environmental compliance is no exception.

But unlike your production, where eliminating waste is a top priority, environmental is often seen as a cost center, a necessary burden rather than an area for optimization.

The truth is, companies are wasting hundreds of thousands to millions on salaries, fines caused by antiquated compliance practices.

Understanding the three sources of environmental compliance waste

Over the past decade, we’ve spoken with thousands of environmental and operations leaders and identified three main sources of waste.

1. Paying high salaries for repetitive, menial tasks

Based on our research, facilities with complex permits spend an average of 30 to 50 hours per month on manual environmental tasks, equivalent to $40,500 in annual labor costs.

Instead of solving problems, these environmental teams are regularly completing data entry and administrative work.

Each facility is different, but here are two common examples:

- Paper-based inspections – Driving on site, scanning and organizing paperwork, and manually tracking corrective actions—for thousands of annually required inspections. If your company has more than 15 facilities, this can take up a full-time position.

- Data entry – If your facility has air and water permits (most industrial facilities do), you're likely paying six-figure employees for mindless data entry: copy-pasting data, entering sensor readings, reconciling spreadsheets, and fixing errors.

2. Frontline workers are silently on environmental payroll

The time required from frontline workers to complete compliance tasks is often entirely overlooked. In reality, each hour spent on compliance paperwork is lost productivity.

The top three time-intensive tasks for frontline workers are:

- Data entry: Imagine a facility that logs chemical usage by hand. Each day, operators spend 30 minutes recording and emailing data—that adds up to 130 hours or $2,600 annually (at $20/hour) for one employee and performing one task. Multiply this across your company, and you've got yourself a six-figure savings opportunity.

- Paper-based inspections: One inspection alone can take an hour, from completing paperwork to sharing updates with the environmental team. Every hour spent on paperwork is an hour lost on the production floor.

- Agency inspections: If your facility is out of compliance, inspectors will pull your staff away from production duties, and operations executives away from their desk.

3. Preventable, six-figure EPA fines

For some manufacturing industries, the average EPA penalty was as high as $263,000 in 2024. Yet, few companies take penalties into consideration when planning their annual budgets.

Most violations are the result of poor compliance systems that allow small issues to turn into massive problems, such as:

- Not noticing permit limit exceedances for years, leading to compliance issues that snowball into six-figure fines.

- Missing records that make it impossible to prove compliance during an audit or inspection.

- Forgotten inspections that leave facilities vulnerable to NOVs.

How to cut the waste in environmental compliance

Environmental software like Mapistry eliminate operational waste by automating compliance tasks, removing frontline workers from processes, and preventing fines:

- Automating up to 80% of repetitive work (e.g, saving $140,000 annually for a 10-site operation) – Mapistry removes the need for data entry and low-value tasks, ensuring seamless compliance without additional labor.

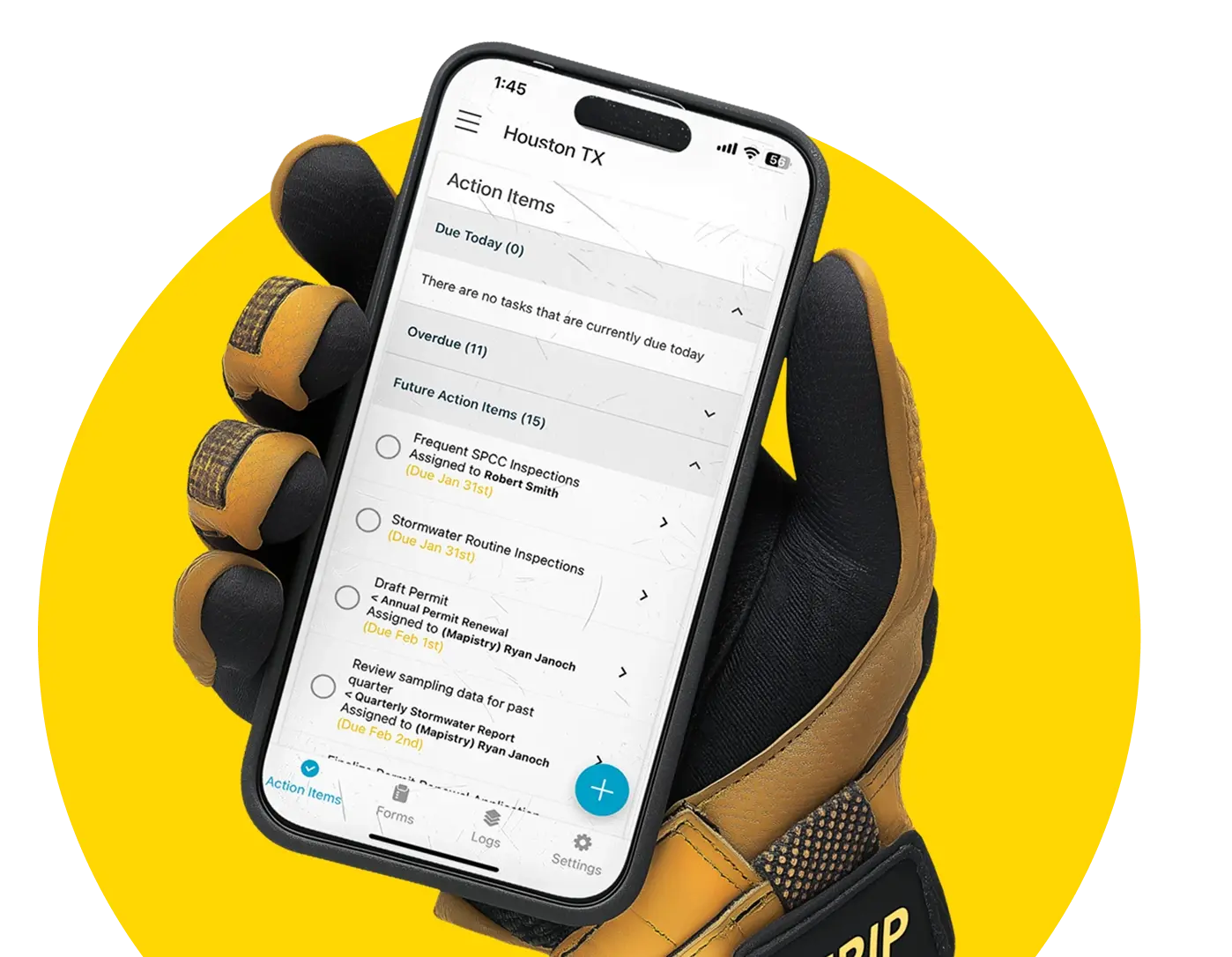

- Cutting operations time spent on environmental – Designed for operations teams, the Mapistry mobile app simplifies inspections, data logging, and allows facilities to instantly provide records during agency inspections.

- Preventing massive EPA fines – With a reliable compliance system and everything in one place, Mapistry significantly reduces the risk of violations.

The result? Less time wasted, fewer compliance headaches, and a leaner, more efficient operation.

Discover how top manufacturers are cutting compliance costs by up to 30%—book a call with us today.

%201%20(2).png)

.png)

.svg)