Environmental Compliance Challenges in Concrete Manufacturing: Josh Neff, Folsom Ready Mix

We had the chance to hear from Josh Neff, the VP of Operations at Folsom Ready Mix. As someone who built his career within the industry, Josh shared how his different experiences and roles exposed him to many types of business functions. Key lessons, like being prepared, staying on top of documentation, and being aware of changes to laws and regulations, were learned due to Josh’s experience.

This perspective has given Josh a greater understanding of how things work operationally and where adjustments can be made to improve processes.

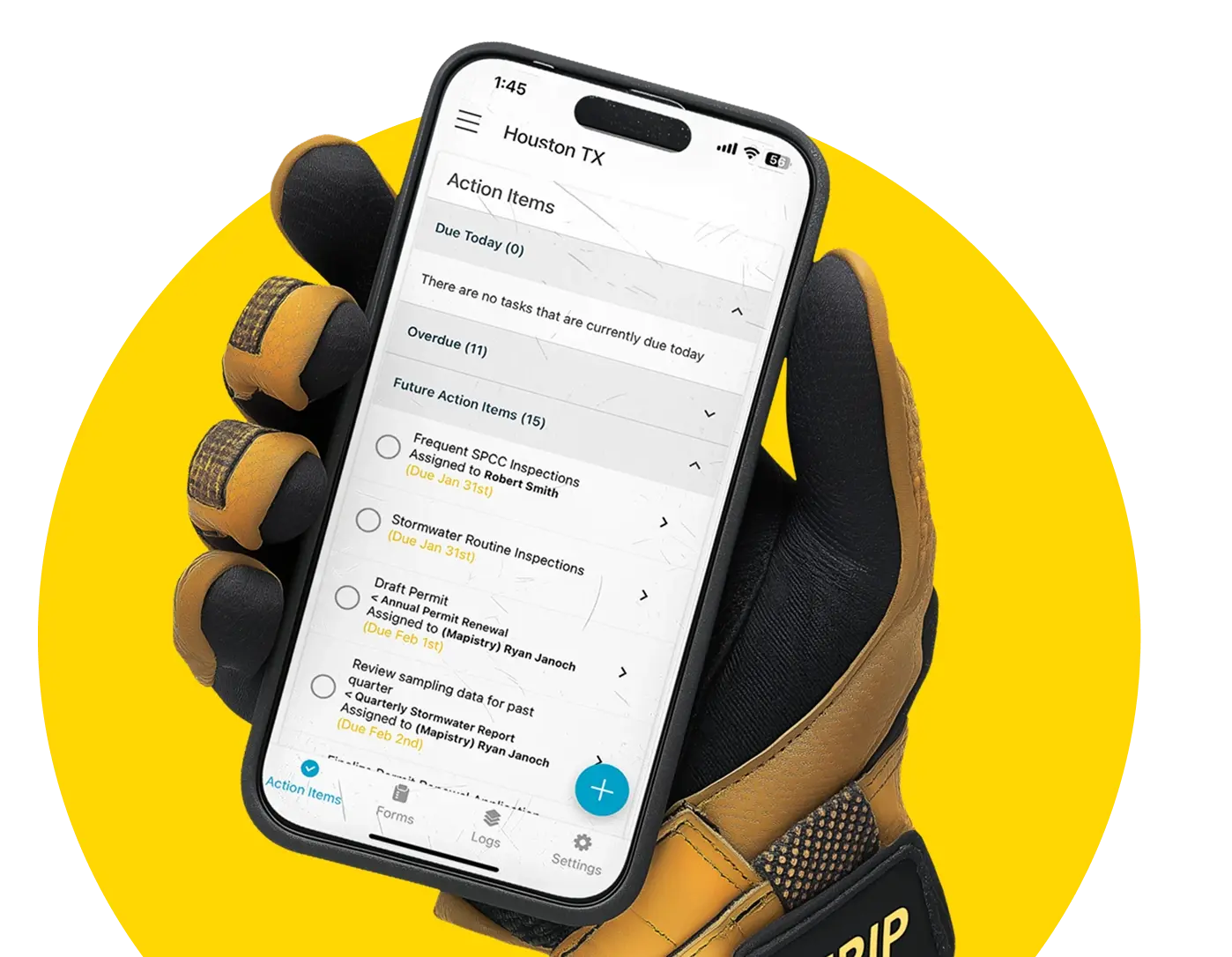

One of the changes he made within Folsom was the adoption of Mapistry, which is currently used to bring consistency and organization to their compliance program. From an operational standpoint, Josh quickly saw the advantages of using mobile tools for faster inspections and greater accountability. Some of the biggest compliance challenges within concrete manufacturing include documentation, which can be solved through digitization. Folsom taps into the tools provided by Mapistry and the support staff to add another level of coverage when dealing with compliance.

To create a stronger EHS program, Josh left us with three c’s: commitment, communication, and consistency. Commit to the process you are putting in place and continue to evaluate its effectiveness. Don’t be afraid to adjust and change course if needed. Communicate the desired outcomes across the chain of command so that everyone understands the “why” regarding the reasons behind implementation. Ensure that processes are followed and consistent, such as on-time monthly inspections or maintaining consistency in documenting and addressing things.

Josh believes that the three c’s of commitment, communication, consistency, and the right tools for the team are key for developing a compliance-minded culture.

Want to learn more?

- Check out our library of previous webinars

%201%20(2).png)

.png)

.svg)